An effective dust collection system requires good components. Hoods, ductwork, filters, and everything in between need to work together to efficiently capture fumes and dust to keep your facility safe. Today we’re talking all about local exhaust hood systems—design considerations, custom fabrication, and why off-the-shelf options don’t always cut it.

The Basics of Dust Capture Hoods

Hoods are a crucial part of a dust collection system. They capture dust and fumes at their source, send the contaminated air through ductwork, and then deposit that into your collector. A well-designed hood captures this dust before it can spread. This reduces the potential for combustible dust explosions and improves workplace safety.

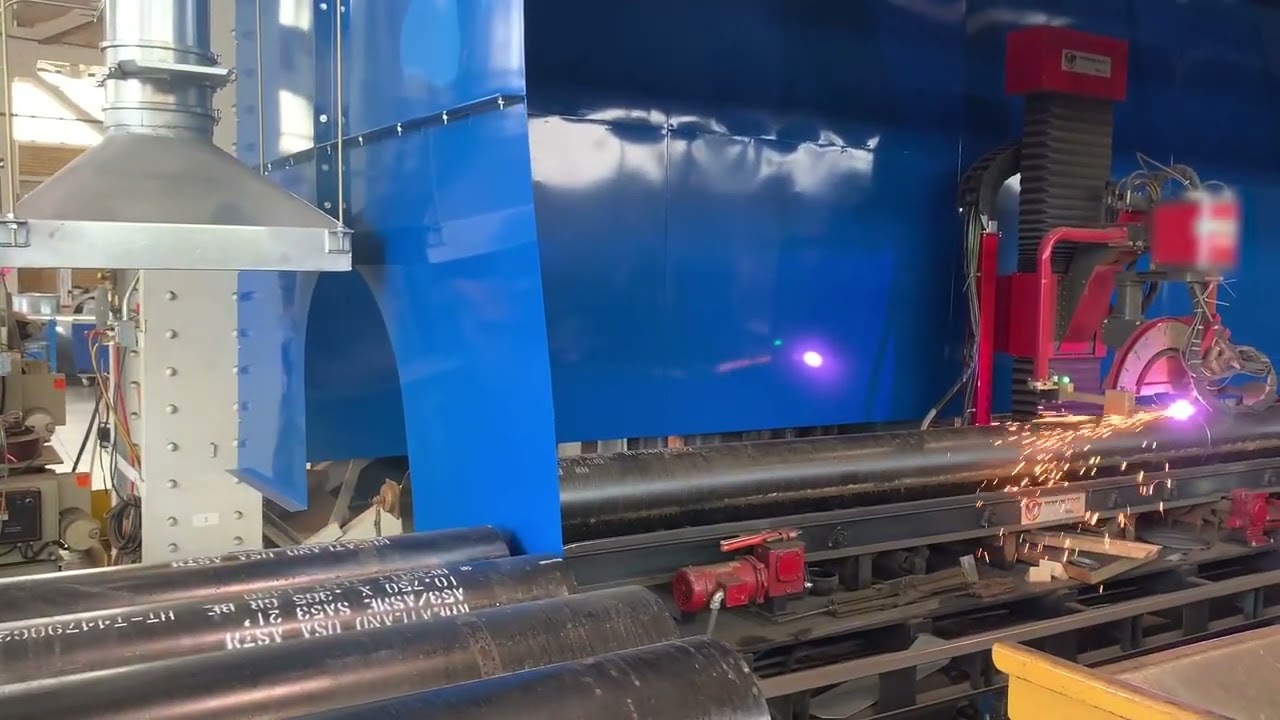

Local exhaust hood systems are used in any process where dust, fumes, chemicals, and vapors are created. Open processes like welding and grinding and many processes in the food industry require hoods. Whether you’re dumping flour in a mixer or making paint, a hood is needed to prevent unhealthy elements from infiltrating your plant.

Our VP of Sales, Mike Zook, has been engineering local exhaust hood systems for over 25 years. He says, “There are two things you need to be effective: containment and capture.”

That’s where proper design comes in. DenTech can look at your entire system and surroundings, not just the hood, to make sure these two pieces are done effectively.

Why Hood Design Matters

Safety

A poorly-designed hood can significantly impact safety in industrial settings. When dust accumulates outside the capture zone, it can affect both worker health and overall operational safety.

Improper hood design can cause worker respiratory issues, along with skin and eye irritation. It can also create fire hazards. When dust gathers on the floor or is dispersed into the air in large quantities, this increases the potential for ignition sources in and around the collection system. Dust on working surfaces can cause employees to slip and fall. And lastly, dispersed dust can make its way into equipment, causing additional maintenance and potential breakdowns.

However, a custom hood can include built-in spark mitigation and will pull dust out of your operators’ breathing zone—making them happier, healthier, and less exposed.

Compliance

An effective hood design is required to meet National Fire Protection Association (NFPA) standards for combustible dust and particulate solids. The new NFPA 660 standard outlines rules on explosion protection, air filtration, maintenance, hazard assessments, and training. If your facility doesn’t comply, you can face major OSHA fines and a potential shutdown.

Cost

A well-designed local exhaust hood system reduces operational costs. By optimizing capture efficiency, your system requires less air volume to effectively collect dust and fumes. This often allows you to use smaller ducts, fans, and collectors, driving down capital and cost of ownership of the system. This results in a cleaner manufacturing environment, which leads to healthier employees and cleaner, higher quality products.

Design Considerations for Effective Local Exhaust Hood Systems

1). Style

Ventilation hoods are classified into two main categories: enclosing and exterior. Enclosing hoods either completely or partially contain the equipment/process that generates dust or fumes. In contrast, exterior hoods are positioned next to the emission source.

Enclosing Hoods

Booth Hoods: enclosing hood that contains dust from your system, using either solid walls or plastic curtains around your equipment.

Exterior Hoods

Canopy Hoods: large, broad capture hoods that are ideal for hot processes like welding to collect rising heat and fumes.

Backdraft Hoods: good for open-top mixers and material loading, these hoods create a horizontal airflow and pull dust across the top of a work surface.

Slotted Hoods: have a more focused capture and airflow, making them an energy-efficient option.

Barrel Hoods: used during drum or barrel filling and emptying, these seamlessly connect to your ductwork.

In addition to these, our team can fabricate custom hoods for any process in the exact size and shape you need. Just give us a call.

2). Positioning

The style is just the start. Where you place the hood is also crucial for effective dust capture. You don’t want fumes pulled across your operators’ breathing zone, so always place your hood as close to the source as possible without getting in the way of your workers or equipment.

The closer you get to the dust generation point, the less air you need to support the system (and the more efficiently it runs). But we know that’s not always practical. Our team is an expert at finding a happy medium where it’s close enough to effectively collect dust, but doesn’t get in the way of your employees or good product. For example, we design and place hoods so they only pull respirable dust in, not actual product.

We also take into account the natural air patterns of the particles and mechanical influences that may impact the dust being generated. For a hot process, we place the hood above to capture rising fumes. Other processes, like grinding, may need hoods to the side to capture dust and sparks as they fly off.

3). Airflow

Hood airflow optimization is another major piece in effectively capturing dust and preventing it from settling in your hood or ductwork. There is a particular capture velocity and plenum speed needed to keep the dust moving into the collector.

The goal is to use as little airflow as possible, but finding that perfect balance requires expertise. If the capture velocity is too low, it allows dust to escape or build up in your ducting. But if your capture velocity is too strong, you’ll experience heavier dust loading, which wears out your filters faster.

Each system and dust type is different. Our team calculates the required airflow based on the size and shape of your hood, how close it’s placed to the source, the size of the work area, and the type of dust. Lead dust, for example, requires a higher capture velocity than weld fumes.

With 40 years of experience under our belts, our team members are experts in hood airflow optimization and design, so we can engineer a solution that works even better than you expected.

4). Material

Depending on the application, we select from a variety of materials for your dust capture hood. Popular options include steel, aluminum, and PVC. Many food and pharma plants use stainless steel, while other fumes and vapors can be handled with PVC. Our engineers know the intricacies of your industry and process to pick the best material for your application.

5). Flash Fire Protection

To reduce the risk of a flash fire, we make sure dust isn’t just sitting in your ductwork. We do this by engineering custom hoods, built around your specific process. For example, if there are sparks in the airstream, we’ll design a method to keep them out of your hood and ductwork so they don’t create a fire hazard downstream. We may add isolation valves or explosion vents in the ducting and collector for even greater protection.

Spark and explosion mitigation are essential in facilities dealing with combustible dust. No matter what we’re fabricating, safety is a main priority on every local exhaust hood system we design.

6). Integration With Current Processes

In our experience, the hardest part of integrating with your process is getting the hood to fit. We don’t want it to interfere with your operators.

That’s why working with a team like DenTech is so important. We look at more than the hood itself, but also the mechanical influences around it when we design your system. Is there room? Is there enough air for the hood to work correctly? And is it easy for your employees to integrate into their process? Because if the operators aren’t using it, it defeats the purpose.

Benefits of Custom Hood Fabrication

Built For Your Exact Application

No two dust sources behave the same, and with custom capture hood fabrication, we can build exactly what you need. We’ll design the system specific to your machines, workstations, production flow, and the type of hazard we are collecting. And since it’s designed specifically for you, you know it’s going to work.

Maybe you have equipment, like a fan, that you can’t move. Don’t worry—we can work around that. Maybe you need better shielding around your hood to create a confined area for the dust. That’s not a problem.

We can find the right solution for every process and make sure it works as efficiently as possible.

Better Performance

The second benefit of custom capture hood fabrication is they are more efficient. They reduce required airflow and lower your operating costs, meaning less energy use, longer filter life, and improved safety of your entire plant. Off-the-shelf hoods are always an option, but they may not be the right hood for what you need.

Most often, we see customers in the food, welding, chemical, and woodworking industries come to us for a custom solution.

Turnkey Solutions

With DenTech, we’re not just delivering a piece of metal, but a full solution beyond just the hood. We look at your whole system—including your ductwork, collector, and controls—to make sure you have the right pieces to achieve your desired results.

We offer in-house design and fabrication, meaning we design, build, integrate, install, and test your local exhaust hood systems.

We have 21,600 square feet of production space. And with welding certifications in SMAW, GTAW, and FCAW, you can trust us to make a hood that’s higher quality and more effective than anything you can buy off the shelf. With every service under one roof, our teams know exactly how each piece fits together in your entire system.

Need a Custom Hood? Work With DenTech

Zook says, “Most of the time, when people come to us with a dust problem, it’s because they don’t have a correctly designed hood.”

- Struggling to meet NFPA dust collection standards?

- Is an inefficient hood design leading to safety risks?

- Unable to find the right hood airflow optimization?

- Need help preventing combustible dust explosions?

Whatever your issue, we can help. After 40 years of custom fabrication, we know the signs of improper hood design. Most importantly, we know how to apply this knowledge to create a custom solution that keeps your employees safe, your workspace clean, and your operating costs as low as possible.