The food and beverage industries face unique manufacturing challenges, from combustible dust to strict sanitation standards. While many manufacturers focus on the upfront price, the real cost of a system comes from downtime, inefficiencies, compliance risks, and wasted product. That’s why industrial solutions in the food industry must be designed differently.

Custom automation, robotics, process piping, and dust collection systems help food manufacturers reduce those hidden costs by streamlining production without sacrificing cleanliness or compliance.

Unique Considerations for the Food & Beverage Industry

All industries can benefit from industrial solutions, but food and beverage manufacturers are especially suited to these upgrades.

- Strict Sanitation Standards: Compliance and sanitation are necessities in the food and beverage world. You need a team with experience in clean design to ensure all solutions meet regulations.

- Assembly Lines: Your reliance on assembly lines and conveyance can be improved through automation, piping, and custom-designed systems to move ingredients and products throughout your plant.

- Dust Control: Many food and beverage plants generate dust at various points in their process, calling for a custom solution to improve the safety of your plant.

- Changing Processes: Every product or packaging change impacts your processes. As you make improvements to your facility, you need a team to implement these changes to ensure everything runs as efficiently as possible.

- Output and Accuracy: The desire for increased output and accuracy makes automation and robotics a natural solution for many food and beverage manufacturers.

Why Food Plants Can’t Use Generic Industrial Solutions

What works in general manufacturing often fails in food and beverage production. GMP (Good Manufacturing Practices) requirements, sanitation demands, and combustible dust risks require unique solutions, such as hygienic design, food-grade materials, and precise engineering. Without them, your facility faces higher contamination risks and compliance issues. That’s why we design for food from the start.

Steve Rapp, President of DenTech Industrial, says, “When creating solutions around the food industry, you need to change the way you think about design. We focus on cleanliness to reduce risks of contamination and bacteria growth.”

Every solution we design balances four things:

- Sanitation and compliance

- Worker safety

- Long-term scalability

- Your operational challenges and goals

Improving Your Facility: Top 3 Industrial Solutions in the Food Industry

1). Automation and Robotics

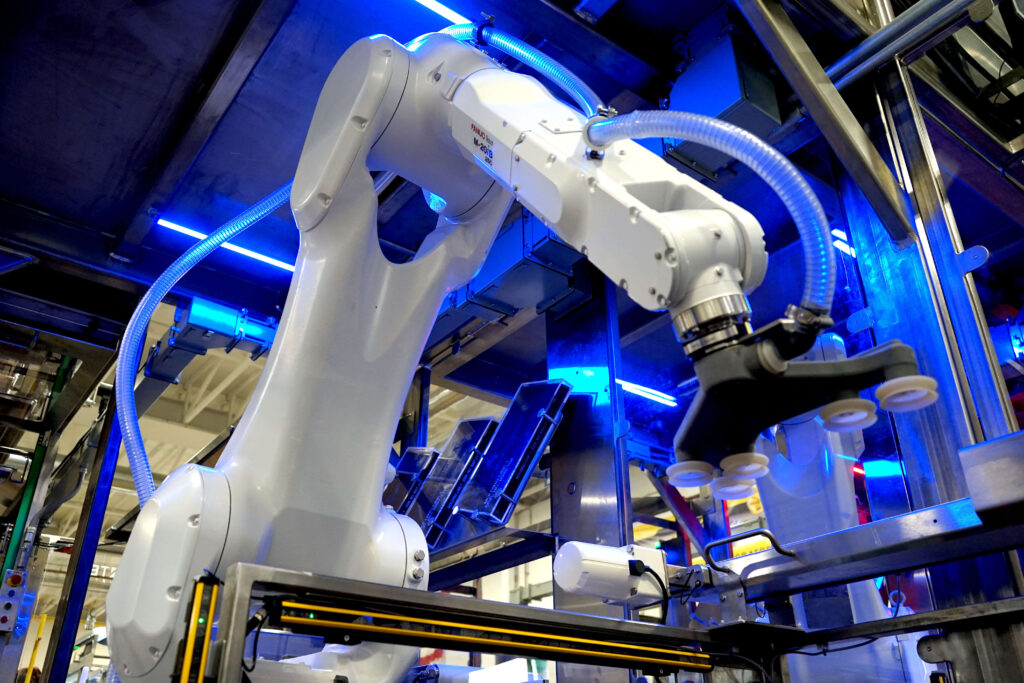

Processes that rely on conveyance or manual sorting are strong candidates for automation and robotics. It comes down to accuracy, speed, and safety. Our systems can help improve the way you pick up, transfer, and package your product at any stage of the process, all while focusing on clean design.

Our industrial solutions in the food industry can’t be pulled from a catalog or found on the internet. They are designed specifically for your application, so every point in your production process is running as efficiently as possible while meeting all food safety standards. Processes like product assembly, carton loading, case packing, palletizing, and more can all be improved with a custom automated system.

Hidden Cost of Manual Processes:

Overtime pay, inconsistent output, higher injury rates, rework, and missed production targets rarely show up as a single line item, but they can quietly drain margins every day.

Benefits of Robotics and Automation in Food Manufacturing

- Increased Productivity: Automation and robotics speed up those repetitive tasks and can run 24/7, meaning more output with less downtime.

- Greater Consistency and Quality Control: Robots are more reliable. They reduce human error and variability, helping you produce uniform products faster and more accurately than a human ever could.

- Improved Worker Safety: Robots can take over dangerous tasks and repetitive motions to reduce workplace injuries.

- Better Food Safety and Hygiene: Automation limits human interaction and potential contamination, allowing you to meet all GMP regulations.

- Saves Money and Reduces Waste: The precision that automation and robotics bring lowers labor costs and material waste, reducing energy usage.

- Custom Made For You: Each system is built for your specific application, so it integrates seamlessly with your existing processes and equipment.

Signs Your Food Plant Needs to Invest in Automation and Robotics

| Problem | Explanation |

| Heavy reliance on manual, repetitive tasks | If employees are performing the same motions over and over, automation in food manufacturing can reduce fatigue, injuries, and labor strain. |

| Bottlenecks or inefficient production steps | When a current process feels slow, cumbersome, or overly complex, automation can simplify and streamline the workflow. |

| Safety concerns on the production floor | Robots can handle hazardous, high-temperature, or high-risk tasks to improve workplace safety. |

| Need to increase throughput and cycle times | Automation in food manufacturing allows you to produce more product in less time without sacrificing consistency. |

| Inconsistent quality or accuracy issues | Automated systems deliver precise, repeatable results that reduce errors and product waste. |

| Desire for repeatable, scalable processes | Robots ensure the same process is performed the same way every time, making it easier to scale production. |

2). Process Piping

Clean design is our top priority when building industrial solutions in the food industry, especially food-grade process piping. Moving your ingredients while maintaining cleanliness, quality, and temperature requires expertise and precision. When designing a system, we look at the type of product being conveyed, the piping system, the material, and the conditions of the room it’s in. Both the outside and inside of your industrial piping need to be sanitary and easy to clean.

Our experts have worked in the food and beverage industry long enough to know the best type of piping system for your application, whether that’s jacketed, sanitary, stainless steel, PVC, and more. Our team doesn’t just design the system. DenTech’s certified welders and pipefitters install it correctly so you can meet all industry regulations.

Hidden Cost of Improper Process Piping:

Frequent leaks, extended sanitation time, product loss, unplanned downtime, premature corrosion, and increased risk of GMP non-compliance drive up operating costs over time.

Benefits of Food-Grade Process Piping

- Ensures Safety and Quality of Food: Clean design provides a sanitary transfer of ingredients (whether that’s liquids, powders, or gases) in any plant environment.

- Improved Process Efficiency: Custom process piping helps you manage the flow of ingredients efficiently, with an uninterrupted transfer, which reduces leaks and downtime.

- Ensures Compliance: Properly designed process piping helps meet FDA and GMP requirements by using approved materials, sanitary welds, and clean-in-place (CIP) designs.

- Easy to Clean: GMP requires fast sanitation cycles to keep your process clean.

- Built for Longevity: Our custom piping is not a temporary fix. These systems are built for long-term service life, reducing the need for frequent replacements or rework.

- Custom Designed For You: In food plants, a “standard” piping system can become a liability. That’s why we design systems specifically for your product, processes, sanitation needs, and environment.

Signs You Need to Invest in Food-Grade Process Piping

| Problem | Explanation |

| Recurring leaks | Leaks caused by failing gaskets or poor welds are a clear warning sign that you need to upgrade your piping system. |

| Corrosion or other damage | Corrosive damage indicates the piping material isn’t compatible with the product being conveyed. Properly specified piping protects your product, extends system life, and ensures safe operation. |

| Adding new equipment or processes | Expanding your production line often requires new or upgraded process piping to seamlessly integrate new equipment with your existing system. |

| Non-compliant or poorly-installed piping | If piping doesn’t meet industry or process specifications, it can create safety risks and inefficiencies. |

3). Dust Collection and Explosion Protection

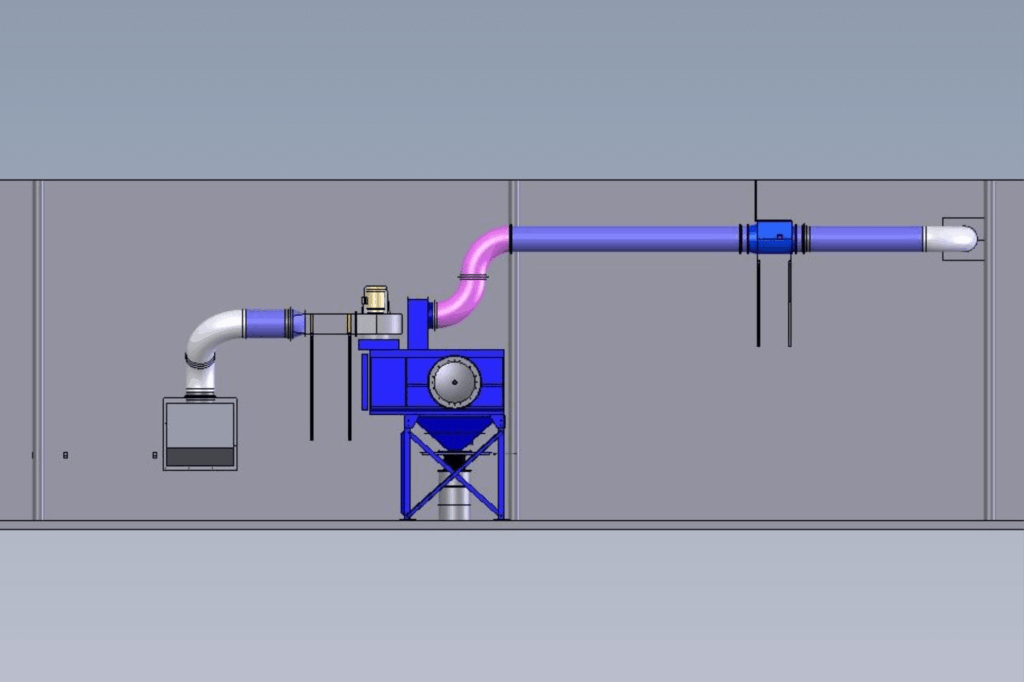

Dust collection isn’t solely a food and beverage issue, but it’s especially important in this industry where flour, sugar, spices, and other combustible powders are prevalent. Dust hazards in food production lines often come from processes like mixing and drum filling and emptying. You need an effective solution to keep workers safe and your plant compliant.

Our team designs, installs, and maintains custom dust collection systems for the food and beverage industries. Maintaining a clean production environment is critical to both product quality and regulatory compliance. This is why industrial dust collection for food processing is so important.

Hidden Cost of Poor Dust Control:

Excessive cleaning labor, lost product, higher insurance premiums, compliance risk, and unplanned downtime can cost more than the dust collector itself.

Benefits of Fire and Dust Hazard Control

- Reduces Risk of an Explosion: When combustible dust is properly collected, it makes an explosion less likely and helps improve safety in your plant.

- Improves Compliance: Efficient dust collection limits compliance issues with food safety standards, so you don’t face fines or employee health problems.

- Limits Product Waste: An efficient system only collects dust, not your product or ingredients, reducing the amount of waste in your process.

- Saves You Money: Our custom systems are optimized to use as little air volume as possible, reducing energy usage, often resulting in smaller ducts, fans, and collectors.

Signs You Need Industrial Dust Collection for Food Processing

| Problem | Explanation |

| Fugitive dust | Excess dust in the air, on your rafters, on process lines, and on other surfaces indicates you need a dust collection system in place. |

| Product contamination | Dust can compromise product integrity, especially in food and beverage manufacturing, where clean processes and product quality is essential. |

| Difficulty meeting compliance standards | Excess dust can put your facility at risk for OSHA, NFPA, or insurance compliance issues. |

| Frequent equipment cleaning and downtime | Dust accumulation leads to clogged equipment, unplanned maintenance, and production interruptions. |

Work With DenTech for Industrial Solutions in the Food Industry

Real cost savings in food manufacturing come from designing systems correctly the first time. With over 40 years of experience working in the food and beverage industries, we know the typical problems you face. And more importantly, we help you come up with a solution.

Our industrial solutions in the food industry are designed to limit downtime. We’ve invested in the facilities and equipment that allow us to prebuild and test components ahead of time. This speeds up the installation process and limits disruptions to your workflow.

We’ve also prioritized training and certifications. When our team enters your plant, you know we have the proper sanitary certifications for welding, safety, and beyond. We will follow regulations, maintain a safe and clean environment, and provide a quality solution that meets every expectation—all while limiting your downtime.

This may seem like a lot to ask, but for us, that’s the standard.

In addition to these industrial solutions in the food industry, we also offer a full suite of in-house services, from fabrication and machining to installation and maintenance. When you work with us, all you need is a single partner to handle the entire process.

This means:

- Easier coordination

- Fewer vendors to manage

- Streamlined communication

- Flexibility in services that can change as you grow