Fabrication

Our team designs, fabricates, and installs custom turnkey solutions for limitless applications. We’re fully equipped in-house to roll, bend, and cut material to achieve an endless variety of fabrications. DenTech will work with you from consultation to project completion.

Our experienced team will manage your project from start to finish:

- Design

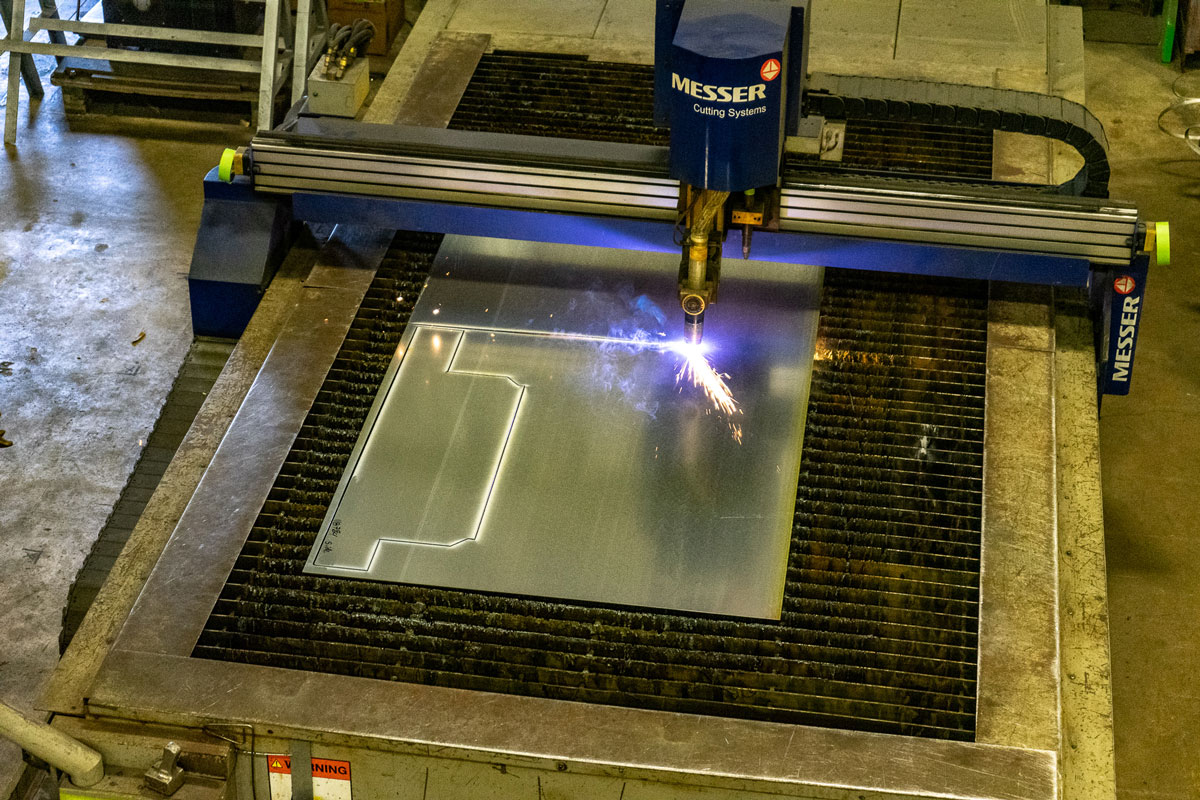

- Cutting, bending, forming, rolling

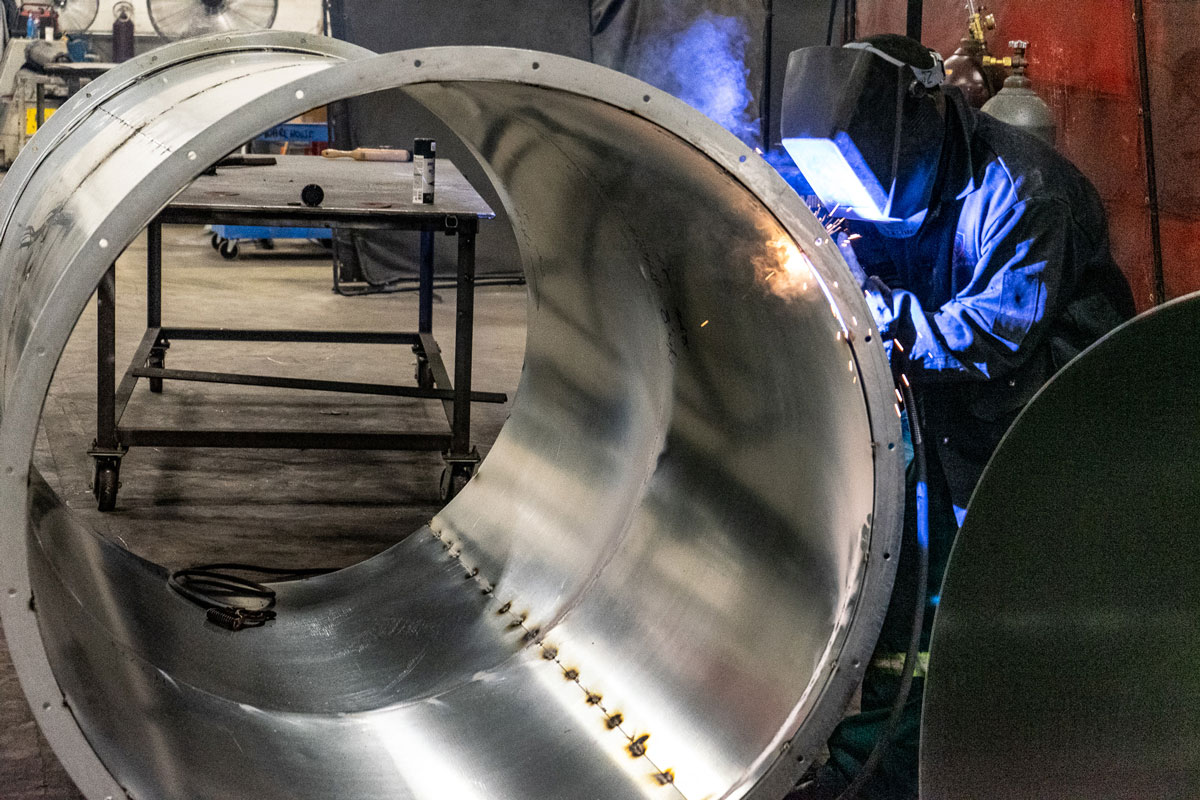

- Welding

- Coating

- Installation and on-site welding

With our in-house capabilities, we’re also able work on any stage of your project.

- Solidworks

- 3D capabilities

- AutoCAD

- ProNest

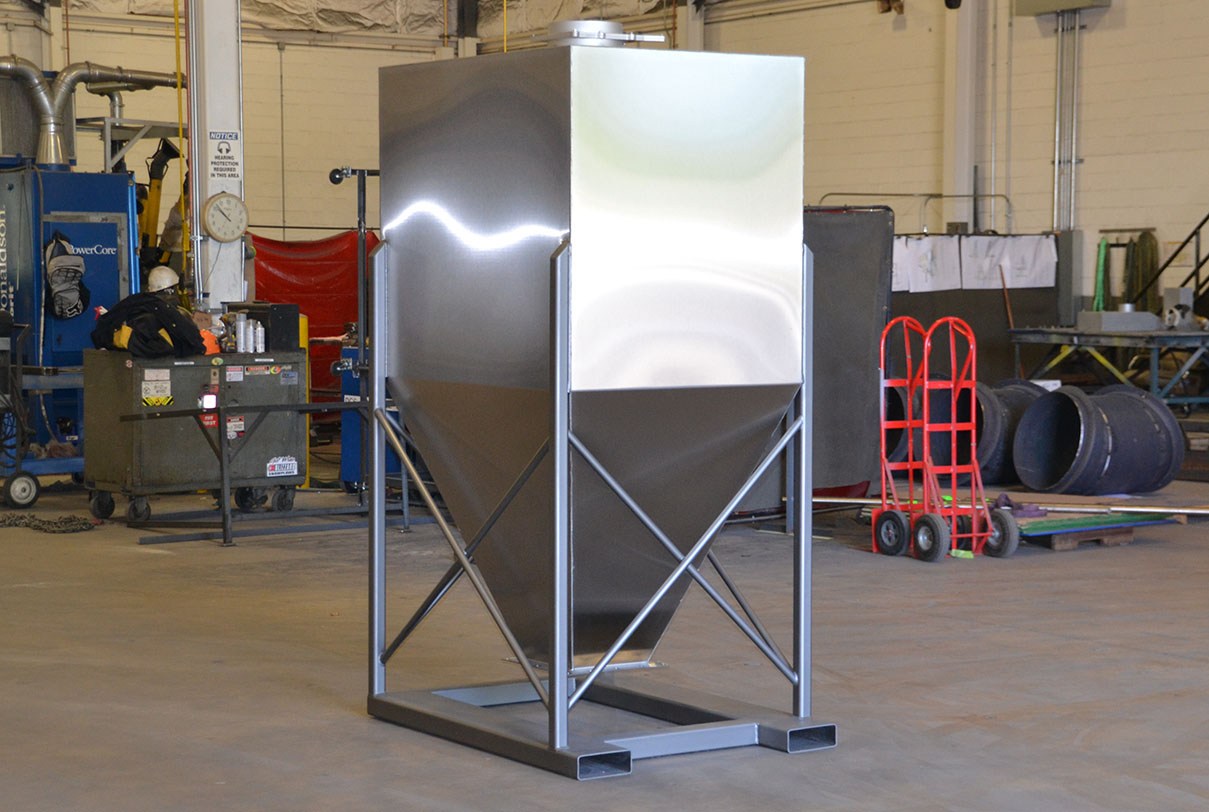

Here are just some examples of what we frequently produce:

- Conveyors

- Carts

- Hoppers

- Cyclones

- Mezzanines

- Storage racks

- Duct work fittings

- Exhaust hoods

- Machine guards

- Structural steel

- Food-grade applications

- Pharmaceutical applications

- Custom weld fixtures

DenTech continues to expand our facilities and equipment with additional capabilities, including:

- CNC HD-Plasma/Oxy-fuel cutting

- Precision plate shearing up to 12′ wide x 1/2″ thick material

- 20″ x 20″ bundle cutting

- Precision bending

- CNC automated saw

- Purge welding

- Aluminum fabrication and welding

- Utility piping and sanitary piping

- Custom solutions to meet your needs

- One purchase order

- Single point of responsibility

- Quick turnaround

- Highly trained and certified team

- 35 years of experience

OUR CUSTOMERS SAY...

It's the gold standard. I look forward to doing additional business with you guys."

Everything working as it should!! Thank you."

Industries Served

This is not a comprehensive list. If you don’t see your industry, give us a call.

LITERATURE

For access to downloads, line cards, case studies, manuals and more, please visit our resources page.